Diverting Organic Waste to the Anaerobic Digester

Step 1: Organic waste is separated

Step 1: Organic waste is separated

Source separated organic waste (SSOW) is placed in a designated collection container at your place of business. Food waste can be contained in plastic bags and/or packaging.

Step 2: Collection and delivery

Step 2: Collection and delivery

Organic waste is collected by your hauler, transported to North Salt Lake and delivered to the Wasatch Resource Recovery facility.

Step 3: Pre-processing/De-packaging

Step 3: Pre-processing/De-packaging

Organic waste is received at the facility and processed by a series of machines that will remove any contaminants or non-food material.

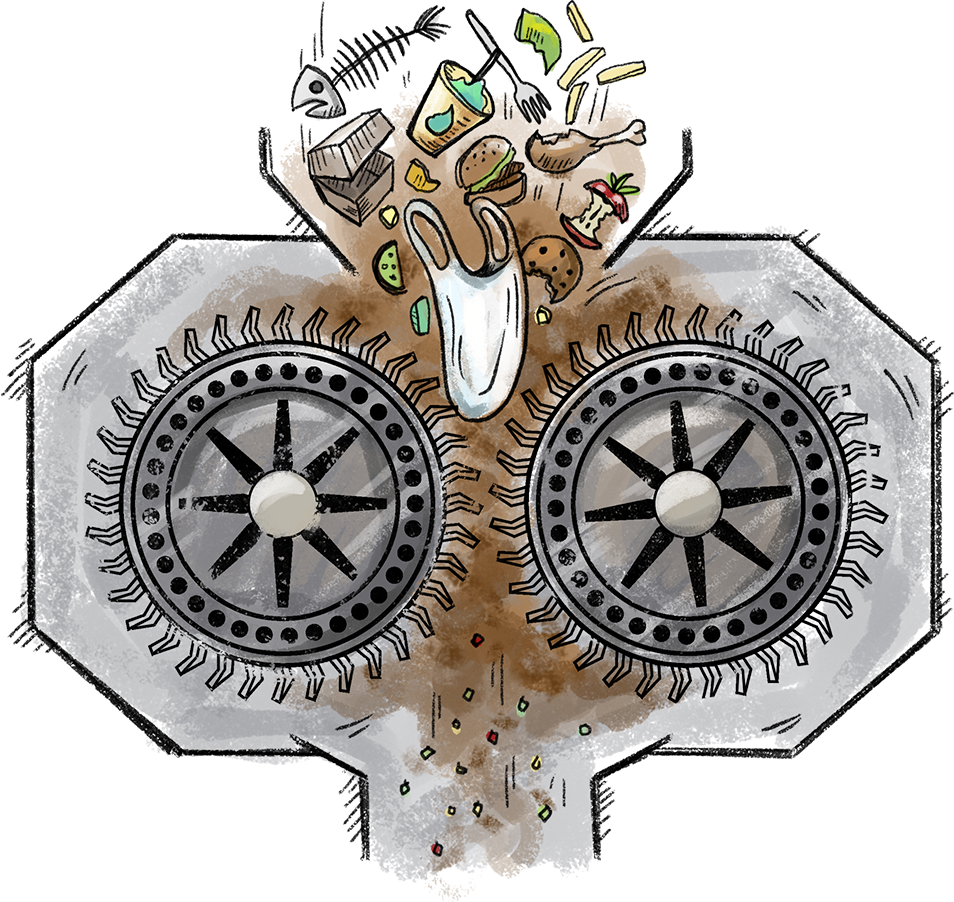

A. Grind

Organic waste enters a grinder where it is chopped into small pieces

B. Liquefy

Secondary water is added to the ground-up organic waste and mixed vigorously until it reaches a liquid state. By using secondary water, no potable water is used in this process.

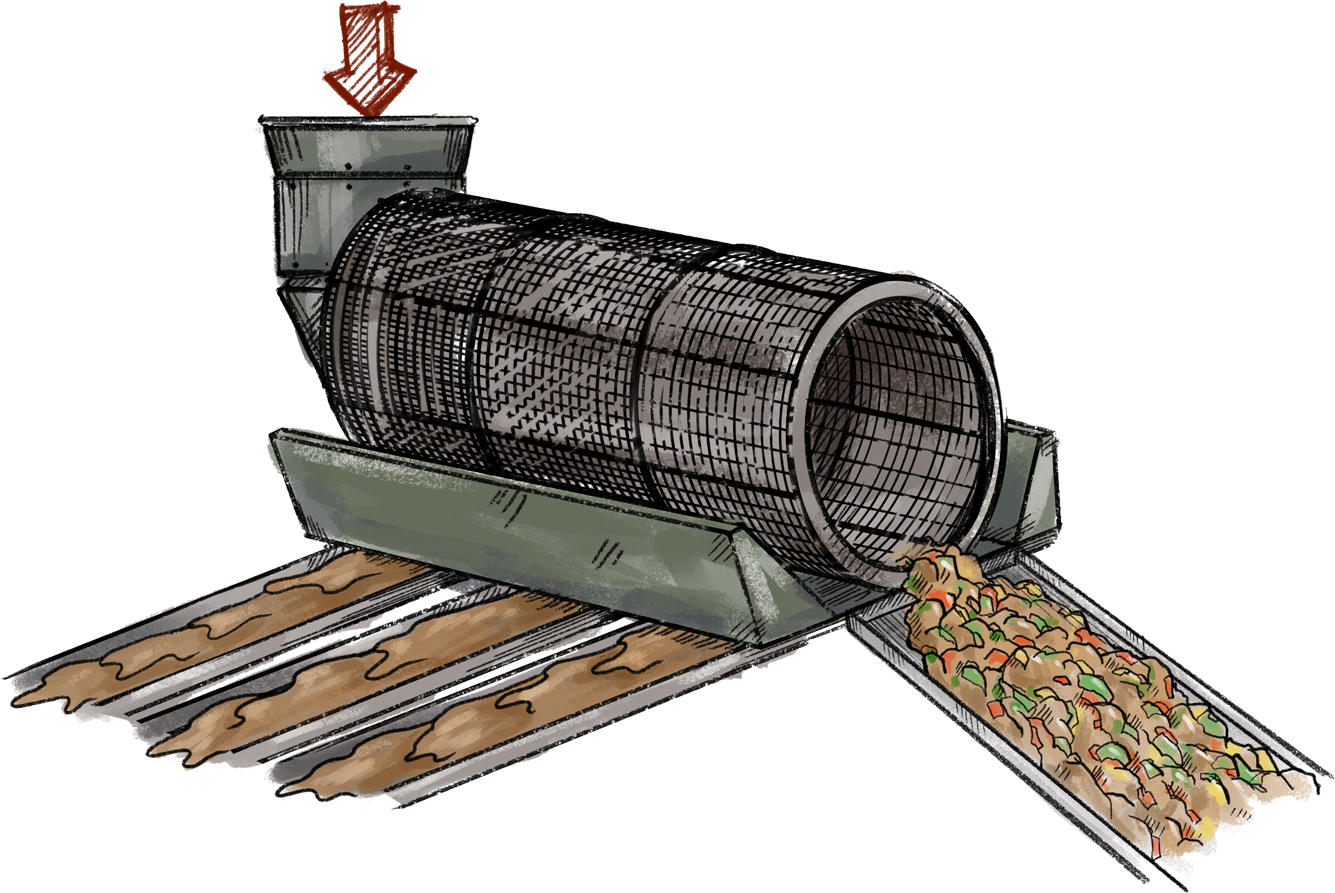

C. Screen

The material passes through a rotating screen where any packaging or contaminants are washed free of remaining organic material and removed, while all organic material is fed into the digester.

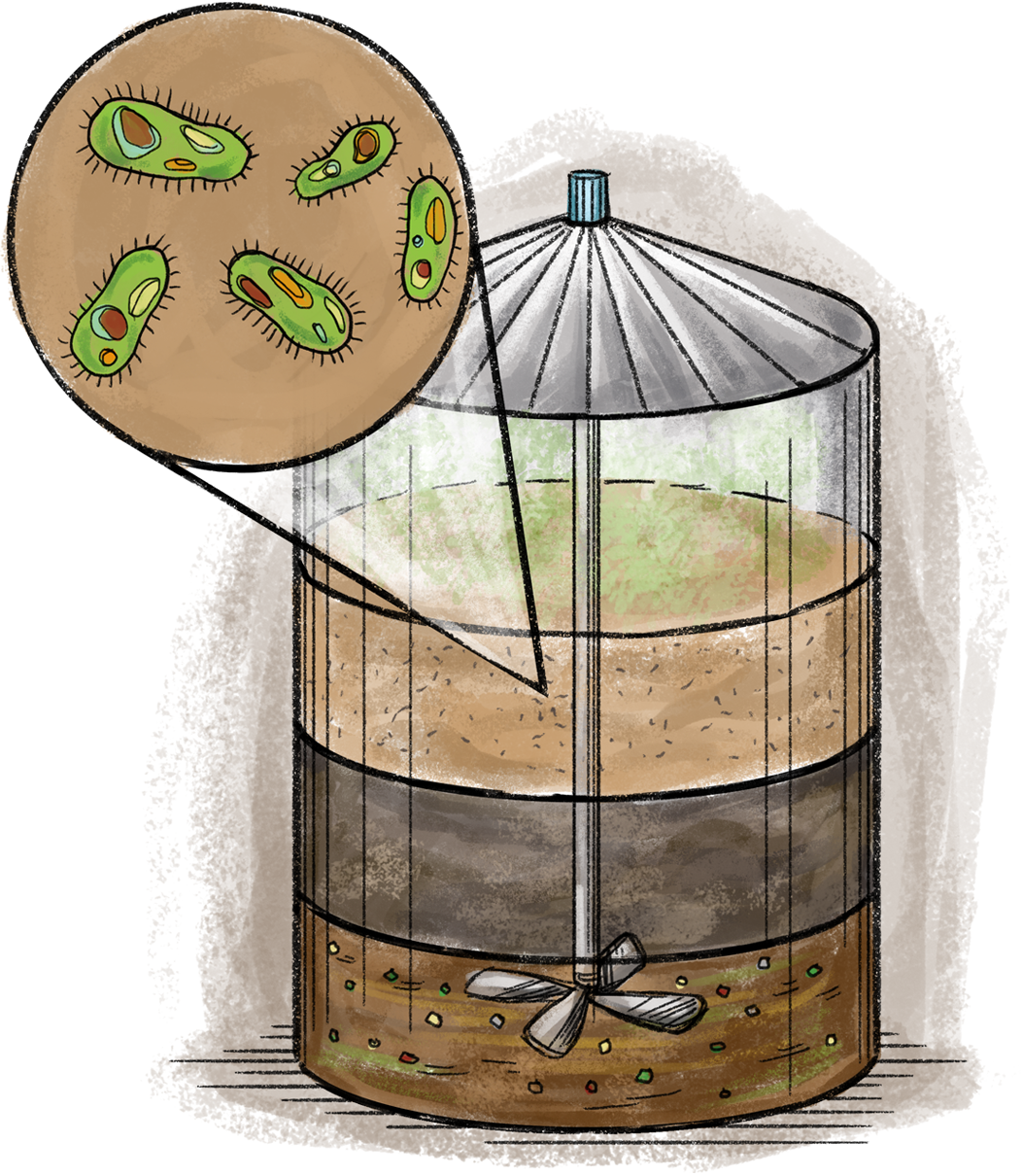

Step 4: Digest

Step 4: Digest

Organic waste in the digester is heated to aid the growth of microbes. These microbes break down in the organic matter, without the use of oxygen, resulting in biogas production.

Product 1: Renewable Energy

Product 1: Renewable Energy

Biogas is captured and purified before it is converted into biomethane (renewable natural gas) and fed into the nearby gas pipeline and sold into the market as renewable “green” power. WRR will supply enough natural gas for approximately 40,000 people or 15,000 homes, a community the size of Bountiful, Utah.

Product 2: Bio-based Fertilizer

Product 2: Bio-based Fertilizer

The remaining product is a nutrient-rich, carbon-based fertilizer used to grow crops.

Additional Info: Organic Waste Facts

Organic waste makes up nearly 30% of our landfills, which, if diverted, can result in considerable cost savings for businesses, institutions and service providers.

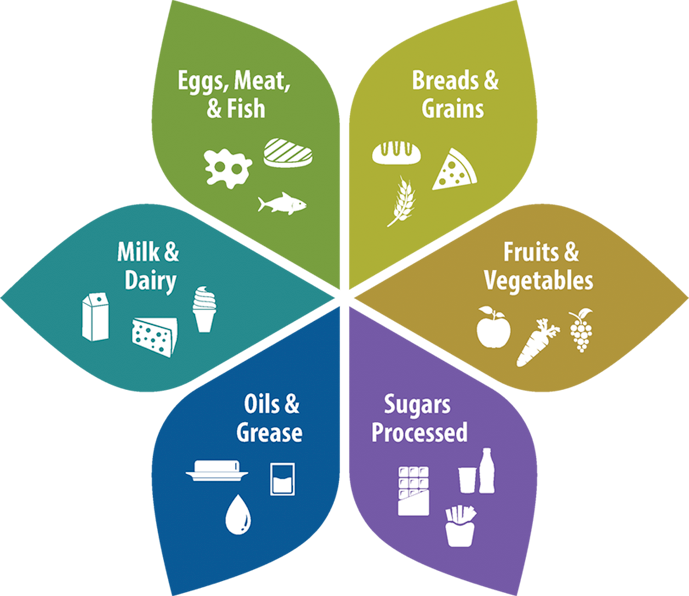

Organic waste can include fruit, vegetables, meat, bones, dairy, fats, liquids, raw food, prepared food, food processing waste, brewery waste, canned and bottled waste, etc.

Tipping fees for the Wasatch Resource Recovery Facility will be considerably less than the average landfill along the Wasatch Front.*

*Based on 7-8% contamination rate by weight.